Floating ball valve is manufactured as 1PC,2PC or 3PC bolted construction.Floating ball valve allows easy maintenance in line due to the possibility of swing-out of the centre section, permits a flexibility in production due to the unlimited combinations of possible end connections and asymmetric construction.

floating ball valve MAIN FEATURES

1. Lost-wax precision casting.

2. Fire safe design approved.

3. Built-in ISO 5211 direct mounting pad for easy automation.

4. Anti-static devices for ball-stem-body.

5. Blow-out proof stem.

6. pressure balance hold in ball slot.

7. TA-LUFT design approved

floating ball valve DESIGN FEATERS

BLOW-OUT PROOF STEM

The stem is downloading with its inverted sealing structure with sealing gasket, the force of inverted sealing structure will increase while the medium pressure in the valve cavity increases to ensure the sealing effect of the stem, in case of abnormal pressure in creasing of the valve cavity, the stem won’t be impacted out. The filler is designed with proper V shaped structure which can effectively convert the medium pressure inside the valve cavity and the locking force of outer gland into the sealing force of stem.

FIRE SAFE SEAT SEALING

According to the user’s requirement, the ball valve can be designed with fire-resistant structure, in case of a fire and the sealing ring is damaged, every sealing part of the ball valve can form the structure of metal-to-metal hard seal, witch can prevent the spreading of both the media and fire.

- During the fire, soft seat (such as TFM1600, PTFE, PTFE and etc) will burn up and lose supporting and sealing functions, then the ball moves free downstream due to pressure from upstream, and contacts secondary metal seats of body or end cap, which comes to a leakage prevention (see figures #1 & #2).

- Grafoil body gaskets can endure high temperature and remain unaffected during the fire, and eventually prevent fluid leakage to the exterior. Moreover, the connection of body and end cap flange maintains metal to metal contact by stud bolts screwed into body (see figures #3 & #4).

- Grafoil packing can endure high temperature and remain unaffected during the fire and prevent fluid leakage to the exterior (see figures #5 & $6).

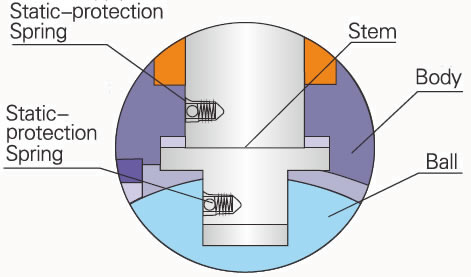

STATIC-PROTECTING CONSTRUCTION

The floating ball valve could be designed as static -protecting construction as required, namely, mounting conductive spring between the body and stem, or between the stem and body, there after the static engendered during opening the valve could be conducted to pipelines then earth through the preset static passage to clear static away, the design works to prevent igniting combustible medium by static fire-striking for the system safety.

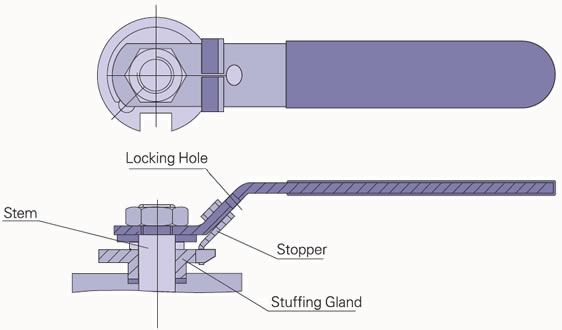

INTERLOCKING DEVICE

For floating ball valve is installed outdoors, preventing non-workers and improper operation of the valves, which collision of its stem in relatively violent vibration occasions easily causes improper operation, a locking bore can be set in the full open position or fully closed position and lock can be used if needed for the purpose of security insurance.

floating ball valve PARAMETER

DN15~250

DIN PN16, PN25, PN40, ASME CL150, CL300, JIS10K, 20K

Flange, Thread (Internal thread or Externa thread

2 pieces, 3 pieces, 3 way

Pneumatic Cylinder, Electric actautor, Manual Actuator

Juice, Starch, Syrup, Water, Oil, Gas

floating ball valve DESIGN STANDARD

| Standard | DIN | ASME | JIS | GB |

| Pressure Rating | DIN 3357 PN10-PN40 EN 12516-1 |

B16.34 CLASS 150(BS5351 CLASS150) B16.34 CLASS 300(BS5351 CLASS300) |

B2001 10K B2001 20K |

GB 1224 GB12237 PN16-PN40 |

| Face to Face | DIN 3202 F4/F18 DIN 3202 F1/F17 |

B16.10 | B2002 10K Form 6 B2002 20K Form 10 |

GB 12221 |

| Connection Facing | DIN 2501 PN10-PN40 Facing DIN 2526 Form C |

B16.5RF Serrated Finish(AARH200) |

B2212 10k B2214 20K |

GB 9113.1 |

| Inspection & Testing | DIN 3230/3,EN 12266 | API 598,API 6D | JIS B2003 | GB/T13927,API 598 |

| Quality Assurance | ISO 9001,QS9000 AD2000-Merkblatt W0 PED 97/23/EC CE0036 API 6D |

ISO 9001,QS9000 AD2000-Merkblatt W0 PED 97/23/EC CE0036 API 6D |

ISO 9001,QS9000 AD2000-Merkblatt W0 PED 97/23/EC CE0036 API 6D |

ISO 9001,QS9000 AD2000-Merkblatt W0 PED 97/23/EC CE0036 API 6D |

info@shxvalve.com

info@shxvalve.com