info@shxvalve.com

info@shxvalve.com info@shxvalve.com

info@shxvalve.comMobile:+86-17717520739

Wechat:17717520739

Email:info@shxvalve.com

Address: NO.720, Suide Road, Jiading District,Shanghai, China.

2020-06-27

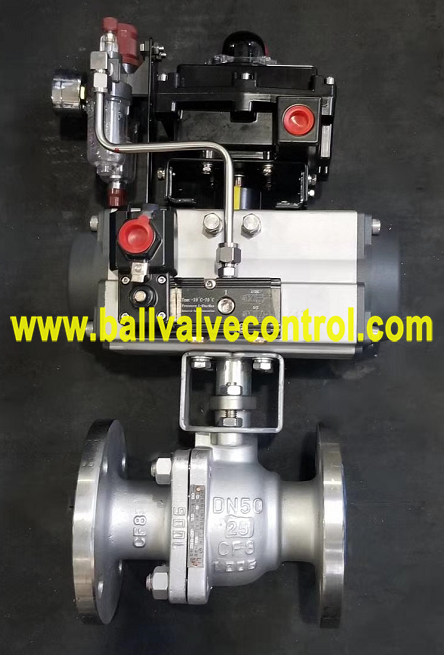

Pneumatic O type shut-off ball valve feature:

Pneumatic O type shut-off ball valve is composed of ball valve and pneumatic double or acting pneumatic actuator.Pneumatic O type shut-off ball valve has the advantages of simple structure, small volume, light weight and convenient operation, and Pneumatic O type shut-off ball valve can be widely used in the automatic adjustment and remote control of petroleum, chemical industry, hydropower, light textile and other industrial production processes.

Pneumatic O type shut-off ball valve is mainly used to cut off or put through the medium in the pipeline, can also be used for fluid regulation and control, compared with other valves, has the following advantages.

1,Small fluid resistance, ball valve is a small fluid resistance of all valves, even if the diameter of the ball valve, the fluid resistance is quite small.

2, The thrust bearing reduces the friction moment of the valve stem, can make the stem long-term balance flexible.

3, The seat sealing performance of Pneumatic O type shut-off ball valve is good, using PTFE and other ammunition materials made of sealing ring, the structure is easy to seal, and the ball valve sealing ability increases with the increase of media pressure.

4, Pneumatic O type shut-off ball valve stem sealing reliable, because the stem only rotary movement and do not do lifting movement, the stem packing seal is not easy to destroy, and sealing ability with the media pressure increased and increased.

5, Due to PTFE and other materials have good self-lubrication, friction loss with the ball is small, so the long service life of the Pneumatic O type shut-off ball valve.

6, Lower valve stem and stem head convex price to prevent the stem ejected, such as fire caused by stem seal damage, convex stage and Pneumatic O type shut-off ball valve body can also form metal contact, ensure the stem seal.

7. Anti-static function: spring is set between the ball, valve stem and valve body to export the static electricity generated during the switching process